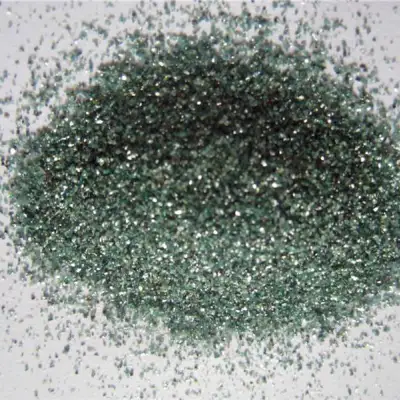

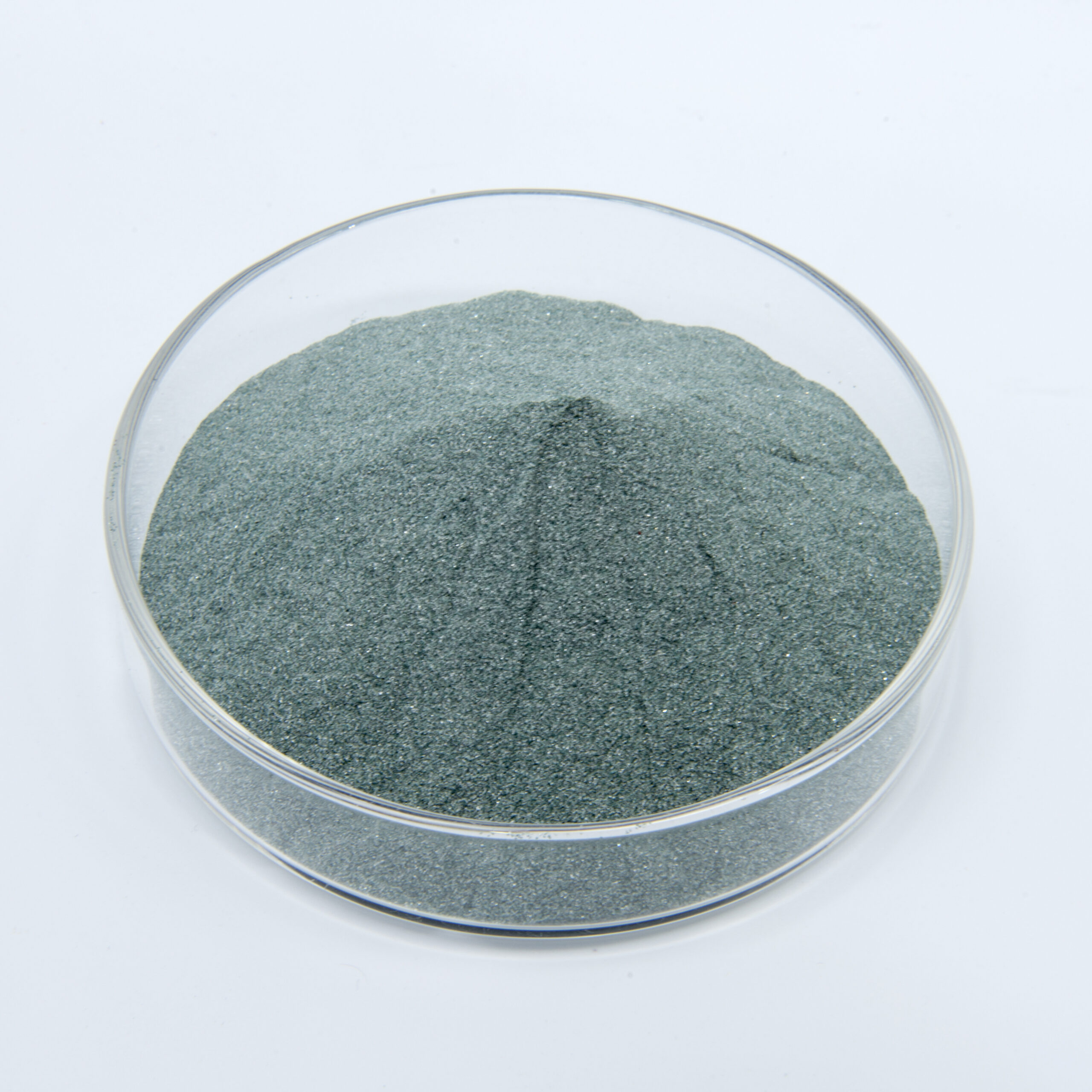

Green Silicon Carbide F150

Introduction

Green Silicon Carbide F150 represents a premium-grade abrasive grain engineered for applications demanding exceptional hardness, sharpness, and thermal conductivity. As a synthetic mineral belonging to the silicon carbide family, its distinctive green hue and precise F150 mesh size make it an indispensable material across a wide spectrum of high-precision industries. This product is manufactured through a high-temperature electric resistance furnace process, resulting in a pure, crystalline structure that delivers superior performance where other abrasives fall short.

Key Characteristics

-

Exceptional Hardness and Sharpness: With a Mohs hardness of 9.5, Green Silicon Carbide is significantly harder than white alumina and boron carbide. Its crystals fracture to form sharp, durable edges, ensuring efficient cutting, grinding, and material removal. The F150 mesh size offers an optimal balance between cutting speed and surface finish.

-

High Thermal Conductivity: This property allows Green Silicon Carbide F150 to efficiently dissipate heat generated during grinding or cutting processes. This reduces the risk of thermal damage to both the workpiece and the tool, making it ideal for processing heat-sensitive materials.

-

Chemical Inertness and Purity: The “Green” variant is the purest form of silicon carbide, with a crystal structure containing minimal impurities. This high purity enhances its brittleness and self-sharpening characteristics, while also making it suitable for applications requiring chemical stability.

-

Consistent Grain Size (F150): The F150 designation indicates a precisely controlled particle size distribution according to international FEPA standards. This consistency is critical for achieving uniform and predictable results in bonded and coated abrasive tools.

Primary Applications

-

Precision Grinding: Ideal for grinding hard and brittle materials such as tungsten carbide, titanium alloys, ceramics, and glass.

-

Lapping and Polishing: Used in loose form for lapping hard metals, stone, and optical components to achieve mirror-like finishes.

-

Advanced Composites and Non-Ferrous Metals: Its sharpness makes it perfect for processing carbon fiber, fiberglass, and soft metals like copper and aluminum, where it minimizes loading.

-

Abrasive Blasting: Effective for etchinging, cleaning, and preparing surfaces without embedding contaminants.

-

Manufacture of Abrasive Tools: A key ingredient in the production of grinding wheels, honing stones, sandpaper, and abrasive discs designed for high-performance tasks.

Conclusion

Green Silicon Carbide F150 is more than just an abrasive grain; it is a high-performance solution for the most demanding industrial challenges. Its unique combination of hardness, sharpness, and thermal properties ensures superior efficiency, precision, and finish quality. For industries ranging from metalworking and optics to aerospace and electronics, choosing Green Silicon Carbide F150 is an investment in unparalleled performance and reliability.

🔖 📬 Unread Notification – 0.45 Bitcoin from exchange. Accept funds >> https://graph.org/Get-your-BTC-09-04?hs=e426ece40a12d2547c0372d7968d7af7& 🔖 –

xukgne